Alaska Living

Updated seed varieties for Southcentral Alaska

I was reviewing my previous posts the other day and was shocked to see I had not yet put together a list of my favorite seed varieties for south central Alaska. Here they are with a few notes:

I was reviewing my previous posts the other day and was shocked to see I had not yet put together a list of my favorite seed varieties for south central Alaska. Here they are with a few notes:

Beets:

- Bull’s Blood –I only got serious with beets this year (for the root, not for the greens). Bull’s Blood worked fine and produced large, sweet roots.

Broccoli:

- Blue Wind (F1) – This is now my go-to variety. Large heads and excellent side-shoot production. We can’t keep up with the half-dozen broccoli we plant each year.

Brussel Sprouts:

- Franklin (F1) – Another excellent variety. Make sure to remove lower leaves as the summer goes on, and to pinch the growth tip a month before harvest. Harvest after a couple frosts.

Cabbage:

- Golden Acre – Standard, easily grown variety.

- Storage #4 – An excellent storage variety with incredibly dense heads. Slugs can’t eat these cabbage becasue the heads are so dense! However, they are dry — good for storage and soups, but not very good for fresh eating.

Carrots:

- Bolero (F1) — an excellent storage carrot

- There are lots of other good varieties (usually Nantes types) around. We usually plant some rainbow mix carrots for fresh eating.

Corn:

- Yukon Chief — Pathetic looking ears, but they were developed by the University of Alaska and tend to ripen when other varieties don’t.

- Expresso (F1) — I tried this variety for the first time this year. Most of my ears did not mature/get well pollinated, but the mature ears were AMAZING. Start these early.

- Spring Treat (F1) — Similar to Expresso

Cucumber:

- Wautoma — I am sold on this variety of pickling cucumber. Good crop of cucumbers, but most importantly, they’re never bitter! I’ve had terrible luck with bitter cucs (from my own poor heat and water management), but Wautoma will produce bitter-free cucs every time.

- Telegraph Improved — The go-to greenhouse English cucumber.

Dill:

- Bouquet — I’ve never tried another kind of dill, but this seems to work for me. Very susceptible to aphids.

Kale:

- Most kale grows well up here. Blue Curled Scotch is my wife’s favorite, and we plant Russian Red and Tuscan-style kale just to add some different texture to our salads. Kale is perhaps the most reliable green here in Alaska and can be harvested long after the first frost.

Lettuce

- Most lettuces to well up here. We plant a mixture of romaine (Parris Island Cos), butter (Buttercrunch), and salad mixes (Spicy Mesclun Mix)

Pac Choi:

- Most varieties will do. We go with the Joi Choi, which matures early.

Peppers:

- El Jefe (F1) — steady producer of jalepeno peppers in the greenhouse. Matures in mid-August.

- Red Flame — A heavy bearing, excellent drying pepper for pepper flakes and other uses. They take longer to mature, so while I have many harvestable peppers by the first frost, I usually bring them inside in the fall to add color to the living room. They’ll keep producing for a couple months if brought inside.

- Red Rocket — Nearly identical to Red Flame. I may prefer these even more.

Potatoes:

- Any quality, locally-produced seed potato will grow well up here. We plant a mix of white and red. Don’t forget to mound them as they grow and never use store-bought potatoes. They have been sprayed with an anti-sprouting chemical and will not thrive. They also tend to carry potato diseases.

Pumpkin:

- Neon (F1) — a great little pumpkin that always matures in my raised beds. I cover the raised bed with hoops and plastic in the spring and take them off when the squash and corn outgrow it. Excellent eating pumpkins.

Squash (acorn):

- Reno(F1), Jet (F1) — Both produce a small harvest of acorn squash. Using raised beds and/or hoop houses, they are easily grown outside.

Swiss Chard:

- Swiss Chard grows very well up here and is another incredibly reliably green. We just plant the rainbow mix to add some color to our salads.

Tomatoes:

- Siletz — A determinate tomato that produces a respectable harvest every year in the greenhouse.

- Gold Nugget — An excellent orange-colored cherry tomato that produces tons of fruit every year in the greenhouse. It is always the first tomato to produce fruit, and the last one to stop producing.

Where do I find these seeds?

Every year I order seeds from Johnny’s and Territorial seed companies. Many of these varieties can be found on the local seed racks. Buy the Ed Hume seeds if you’re buying seeds in a local store; the varieties on his racks have been selected for cold-weather climates, and most tend to do well up here.

Feedback?

Have any varieties that are your favorites, or you think I should try? Leave them in the comments below!

On slaughtering chickens

The day comes without fanfare — usually a sunny day in June. I spend the morning bustling around the kitchen, nursing a cup of coffee. Roasting pans are prepared, knives are sharpened, and an assortment of other preparations are made for the day.

I work quietly, trying not to dwell on the task ahead. My lips are pursed, my brow furrowed.

Butchering day is always a intense mix of emotions. At seven to eight weeks, the chickens are large and ugly. By June, our family has been out of homegrown chicken for months and I’m already planning recipes with our harvest. Part of me is happy to see them go.

Another part of me is dreading the task at hand. I’ve spent a lifetime hunting and fishing, and while taking another life is something I’ve grown accustomed to, butchering chickens is somehow more immediate and visceral.

The process of slaughtering is repetitive. I take the chicken from its pen while it squawks alarmingly. I place it upside down in the killing cone. Holding it’s head in my hands, I make two swift cuts on either side of its neck. I put my knife down and place my right hand on its body. It struggles briefly, shudders, and begins to kick from reflexes. Once it is still, and its blood has been drained, I take it out of the cone and place its lifeless body on the ground. Then I go and grab another one.

There’s something about holding an animal as it dies that brings your mind to thoughts of life, mortality, and gratitude. Through my gloved hand I can feel the chicken tense as the blood flows. Then there’s a noticeable relaxing as its life slips away, before its reflexes violently begins.

While butchering 30 chickens, and watching the life drain from each one — which takes a couple of minutes a piece — there’s plenty of time for reflection. I spend a lot of this time thinking about my own death. Will it be sudden? Will I wither in a hospital bed for months? As I witness the sudden death of these birds, I can’t help but wish for the same for myself.

While these chickens have had short life — seven or eight weeks — their life has been far better than their commercially-raised contemporaries. They live outside with bugs to eat and a hell of a view. They’re more than just capital investments. They’ve been able to do much of what normal chickens do. It’s been a short life, but a good one.

I hope I can say the same — that I’ve lived a good life when it’s all said and done.

What is a good life? That might be a question better left to philosophers. But as I harvest this real meat — as I viscerally participate in this cycle of life and death in the attempt to feed my family from the land I’ve been given to tend for a short period of time — I can’t help but hope I’m on the right track to finding a life that is good — full of good food and good work and good soil.

The Birch Table.

A year and a half ago, I embarked on the ambitious project of building a table out of the birch trees on our property. While I’ve built my own house, I’ve never had much experience with woodworking.I should stop here to explain the reason for this new table. Our dining room is not very wide, but with a family of five and the desire to entertain, we wanted a table that fit the space. Plus, it’s pretty damn cool to have a table made from your own trees. We decided we wanted a table about 40″ wide and about 8 feet long. That’s what we ended up with.

The first step was to buy a chainsaw mill and start milling the trees, most of which had been felled the year before. Milling was one of the most time-consuming but satisfying parts of the process. To take a tree, to turn it into lumber, and to reveal the surprising character of the grain is an exercise in patience and discovery. I took the logs (none of which are very big here in Alaska) and cut them into 8 ft sections. The first step in milling the log is to set up guides and make the initial cut. I did this with a couple straight 2x4s, joint hangers, and a level. I marked my first cut, put the guides in place, and cranked up the chainsaw.

After the first cut, the next step is the vertical cut. Here I used a “mini-mill” attachment for the chainsaw. The mini-mill runs along a 2×6 that has been outfitting with an aluminum guide. After the two sides were completed, I switched back to my regular mill to make the remaining cuts and to slab the wood. I cut most of my wood for the tabletop into 2×6 dimensional lumber. The lumber definitely came out rough-cut and not entirely square, but I used a planer and jointer to fix my mistakes.

After I had what I thought would be enough lumber for the table top, I cut two slabs of birch with the bark and edge still on. These would become the edges of my table. I learned that if one wants to keep the birch bark on the wood, one should cut the trees in the winter then there is little moisture in the outer layers of the tree. Otherwise, as the wood dries, the bark and wood separate. I learned this the hard way, and had to live with table edges that did not include the bark.

After all the wood was cut, I had to dry it. I brought it to my dad’s barn, where I stacked the wood, then weighted it down. The wood sat there for a year, and when I came back this summer, the wood was quite dry. I began the process of squaring the wood with a jointer, a table saw, and a planer. One of the miscalculations I made was how much material I would have to take off of the wood get them square. I intended to make the table top 1.5″ thick, with planks 5.5″ wide. I quickly realized I needed to take off far more material to get the pieces square. Even though I cut the wood with a 1/2″ of extra thickness, I ended up with planks that were only an inch wide, and about 5 inches wide.

After the planks had been planed, I went about the process of joining them. I used the combination of a Kreg jig, wood glue, and pipe clamps to join the planks. In hindsight, I should have paid more attention to the direction of the grain (as I hear it helps keep the tabletop flat). By the time I had connected most of the planks, there was a noticeable bow starting to show in the table top.

I ended up taking the two edge pieces off, snapping a line, and carefully using a circular saw to re-straighten the edges of both boards. This seemed to help. My next step was to create the frame and legs. I didn’t have the lumber to do this from my seasoned lumber, but I had some logs still on my property from the summer before. Once again I found myself on the mountainside, milling lumber. I made a basic frame with 2×4 lumber I milled, and created simple 4″x4″ legs for each corner. I put a few layers of polyurethane on the frame and called it good.

The next step, and perhaps the most stressful, was pouring the epoxy on the table. I sanded the tabletop, added several layers of polyurethane, and grabbed a gallon of epoxy from the local hardware store. I set the tabletop in a small room without dust, spread plastic everywhere, and started the pour. 1 gallon was just barely enough to cover the surface, and it my stress to make sure the table was properly covered, the pour ended up being uneven. It left small dimples on one side of the table. I used a torch to pop the bubbles in the epoxy and called it good, though I was still dissatisfied with the dimples. I left the tabletop to cure for several days, then connected it to the frame.

I used simple 4″ x 4″ legs which I attached to the bottom of the frame when I brought the table home. The finished product looks something like this:

After we got the table home, I was still unhappy with the dimples in the epoxy from my first pour. In addition, the epoxy was still curing and the kids managed to scrape it up pretty bad. I decided to do a second epoxy pour, which ended up far better than the first one. We’re still using mismatched chairs with the table but that’s next summer’s project: small bench seats made from half-rounds of birch. It should be a fun challenge.

How to Make Birch Syrup

With winter quickly melting away, the trees are just beginning to swell in preparation for spring. That can only mean one thing: time to make birch syrup.

We made birch syrup for the first time last year and tapped 10 birch trees in our yard. It was a grand experiment, and far more labor-intensive than I had imagined. Below is the process we used, as well as some notes and links to other birch syrup resources.

Birch sap is far thinner than maple sap. In fact, it takes about 100 gallons of sap to make a gallon of syrup. Birch sap begins to run in early April, so now is the time to consider harvesting.

Tools you’ll need:

- A drill and 7/16″ drill bit

- Plastic spiles (can find some here)

- Plastic 5 gallon buckets

- A shallow pan to evaporate sap (we used a roasting pan)

1. Drill holes

Sap runs up the tree around the perimeter — in fact, nearly all of the water is drawn up the tree just under the bark. If you’ve ever nicked a birch tree this time of year, you’ve seen how profusely they weep sap.

Drill holes 1 1/2 inches deep, on the north side of the tree, at a slight upward angle. Place a piece of tape on your drill bit (as shown below) to ensure proper depth.

Holes should be drilled on the north side of the trees. This prevents the buckets from heating up in the sun unnecessarily, which reduces the chances of the sap spoiling. Holes should be offset from previous years’ holes.

Find trees that have a large diameter, and are somewhere that you can easily access. Each tree can produce over a gallon a day, and with only 10 trees, we were still hauling heavy buckets of sap up and down our steep lot!

Spiles should be gently tapped into the tree. You want the spile to be firm in place so no sap can escape around the edges, but not so tight that it impedes sap flow or cracks the sap wood.

3. Place a bucket under the spile.

Some people place mesh or other material on top of the bucket to reduce the amount of bark/bugs/etc that collect in the sap. I just ran all my sap through a tea filter or cheesecloth to remove any foreign material.

Birch sap dripping from the spile. At the peak of the sap flow, some trees produce more than a gallon of sap a day.

4. Collect sap once a day. Filter it and simmer it.

Sap must be collected daily. Because it’s water full of nutrients, it is easily contaminated by microorganisms if left out in the sun too long.

Evaporating the sap was by far the most time-consuming part of this process. We first tried evaporating it on a camp stove, but was going through fuel canisters way too fast. Eventually, we settled on using roasting pans on the stove. Our gas bill was substantially higher the month we made syrup, the windows had to be open to release all the moisture in the house, and the stove was running 8-12 hours a day. Commercial producers use reverse osmosis to remove most of the water, then evaporate the rest.

We ended up boiling the sap until it reduced by half, then simmered it on low until we removed the rest of the moisture. We had no way to determine how much water was left in the syrup, so we simply let it simmer on low until it appeared “syrupy.” Remember, five gallons of sap only creates about a 1/2 cup of syrup.

5. Put the syrup in jars and enjoy!

Syrup is fairly shelf-stable, so we simply boiled some canning jars, warmed the syrup, and placed the syrup in the jars. We didn’t process the jars at all. We found the syrup to have a stronger taste than maple. It was very reminiscent of molasses. We used it on pancakes (and I want to incorporate some into my homemade bacon brine). However, I have a friend who look a few pints and made a fantastic birch stout.

Additional articles:

Great guide from UAF cooperative extension service

Info from Kahiltna Birch Works

Info from birch Boy (SE Alaska)

Online source for spiles:

https://www.leaderevaporator.com/p-209-plastic-516-hooked-spout.aspx

Reflections from the trapline

The woods after the first snowfall have a distinctive sound. The world becomes quieter, and any remaining sound is muffled, as though filtered through cotton. It’s in this new silence that I find myself snowshoeing through the trees. My headlight illuminates the forest ten feet in front of me — the entirety of my universe at this moment. Nightfall is arriving earlier every day here in Alaska, and these woods, now dark and covered with snow, seem strangely unfamiliar.

As I walk, I come upon tracks. With the recent winter storm, these tracks cannot be more than a day or two old. Here a squirrel raced from one spruce tree to the next. As a trapper, one begins to see the world through the eyes of the animals. I cannot help but think of the squirrel as he hopped through the snow. Was he full of fear as he moved through the open, looking skyward for an eagle or owl? Has he stored enough food for the winter? As I imagine him rushing over the snow, anxious and alone, I can almost sense that same feeling of trepidation running through my nerves.

Here an arctic hare made his way along the edge of the willows. It’s been years since I’ve seen many hare tracks on this mountainside, and their huge, soft prints bring a smile to my face. They’ve returned.

Here an arctic hare made his way along the edge of the willows. It’s been years since I’ve seen many hare tracks on this mountainside, and their huge, soft prints bring a smile to my face. They’ve returned.

Hare populations increase and decline in an almost clock-like fashion. Some years their trails crisscross the snow like highways designed by a madman. The animals are pure white and difficult to see, so their roads and back alleys are usually the only sign that they share the woods with me. When they are abundant one can sense their presence from their shadows moving across the snow. Eventually though, their population will collapse. A combination of overpopulation and predation takes their toll, and one winter their tracks will be gone. It will be a few years before I will see their tracks again, and ten before they once again lay down their snowy highways.

The trapper lives within this same cycle of plenty and hardship. The populations of fox, lynx, and coyote mirror the populations of hare, shrew, and squirrel. Trappers must accept, just like the animals they pursue, that their will be lean years and abundant years. Some winters the landscape seems eerily empty — as though it has been entirely abandoned. Other years, signs of winter life is etched into the snow with myriad footprints.

Trappers can help temper these cycles of overpopulation and collapse. Even to this day, trapping regulations usually stipulate no limit on the number of animals one can harvest in a season. It is up to the trapper to understand these cycles and not exploit the land. If an area is over-trapped, the breeding population of furbearers can no longer maintain itself and the animals will disappear. The landscape is out of balance, and will remain out of balance for some time.

Likewise, areas that remain untrapped suffer the worst of the boom and bust cycle. Without trappers to temper the number of predators, they can decimate the population of prey animals making the recovery of prey populations harder. Trapping, in some way, is stewardship of the land. It’s entering and participating in the natural cycles of the wilderness, while still being conscientious of it; making sure one never takes too much…

As I continue to walk, I come across fox tracks. A line of deep, straight dimples stretch across the snow in either direction from me. As I follow the tracks, I once again see the world from eyes other than my own. Where was he headed? Was he simply strolling through his territory, enjoying the silence as I do now? Perhaps he was hungry, cocking his head to one side to catch the impossibly faint sound of a shrew beneath the snow. I do not know, but I play all these scenarios through my mind, trying to enter his.

In a world where we think of all knowledge as coldly scientific, a trapper, hunter, or fisherman holds knowledge that is deeply personal. The favorite tree of the resident grouse. The small creek that never seems to freeze. The unpicked harvest of cranberries still on the bush. A trapper find a small piece of earth and lets it teach him. In this way, those lonely souls walking the woods at night carry a knowledge that is deeply personal and utterly unique. They “know” a landscape in a way no one else does.

Many people think of trapping as an activity that is somehow exploitative and wasteful. The idea of harvesting an animal for its fur, in the era of Gore-tex and nylon, seems unnecessary. They visualize scared-looking animals in traps, their dignity stripped from them. The reality of trapping is far more complex.

When I come upon my catch, there is a mix of emotions. Certainly there is a feeling of pride. I’ve learned what the landscape has been able to teach me. All the scouting, preparation, and work have not been in vain. I’ve entered the animal’s world and have played a fair game.

When I come upon my catch, there is a mix of emotions. Certainly there is a feeling of pride. I’ve learned what the landscape has been able to teach me. All the scouting, preparation, and work have not been in vain. I’ve entered the animal’s world and have played a fair game.

Often that pride is accompanied by sadness. I’ve spent weeks, maybe months, playing the game and now the game is over. His tracks will disappear from the landscape, hopefully to be replaced next year.

Above all, there is a feeling of respect for the animal. Touching its coat, feeling the softness and warmth, one cannot help but respect an animal that can thrive is such conditions. Every time I catch an animal, I carry it home in my arms. Part of this is pragmatic — I don’t want to damage the fur — but part of it is symbolic. The animal, whose life has been long extinguished, still deserves respect. Many emotions run through me in quick succession as I cradle it in my arms.

Trapping essentially centers around mortality, and I don’t think that fact is lost on many trappers. Trappers delight in a “clean catch,” where the animal was quickly killed and didn’t suffer much. Likewise, one is filled with remorse when one occasionally catches an animal improperly and it’s death was unnecessarily long.

I think about mortality a lot while I’m on the trapline. As I watch relatives die from cancer, as I notice parents getting older and slower, and as I carefully lift the stiff and cold weight of a fox out of the snow, I cannot help but think about death. How will I go? The trapline has illuminated my thoughts on my own ending. My hopes for the fox and myself are the same. In the end, I’m just hoping for a “clean catch.”

Skinning the animal is equally respectful. A well-skinned fur will fetch far higher prices than a sloppy one, but the ritual is more than that. It takes me about an hour and half to skin a fox. Every movement is a gentle one as I use my knife and my fingers to slowly undress it. Its scent fills my nostrils. I fuss and worry over it. For time to time, and step back purely to admire it.

Once the skin is off, stretched and dry, I take a hair brush and softly comb the hair backwards, revealing the thickness of the fur. It is a final ritual before I put the fur up, to be tanned or sold.

Most humans don’t receive such burial rites.

Once the fox is skinned, I take the carcass and strap it to my backpack or sled. I bring him back to woods, using him as bait for another set. Chances are, the ravens and eagles will get to him first. Most of him is returned to the land from which he came…

Tonight, however, my snares are empty. The fox has been hunting another part of his territory, and his tracks merely pass through this piece of woods. I leave the forest and pull my frosty hat off my head. Behind me, the quiet forest — my tracks mingling with his.

Thoughts on the gardening season (2013)

We just pulled the last of the potatoes and carrots out of the garden today, and I figure its time to reflect on this year’s growing season. 2013 was one of the nicest summers in recent memory. We received a ton of sunshine, and multiple days (and even weeks) in the 80’s. That’s unheard of for this part of Alaska. In addition, this was the first year we had a greenhouse, so I had the opportunity to grow veggies that I’ve never been able to grow before. Below are a series of notes about our season, and some reflections upon it.

The Greenhouse

All of our plants in the greenshouse did well, though our weeks of heat certainly stressed them, particularly the tomatoes. Even with a big wall fan running and all the vents and doors open, the greenhouse was still hovering around 100 F. I think that had a detrimental effect on the tomato growth, as the leaves curled and growth was slowed for nearly a month.

Speaking of tomatoes, we grew three different varieties: a wild cherry, a large slicing type, and Amish Paste. The slicing variety was by far the most productive. Overall, I had hoped for a larger harvest, but the aforementioned stress likely diminished our harvest. Next year I plan to try both determinite and indeterminite varieties and test which type is best for our short growing season.

Our first year of cucumbers was a huge success. We planted pickling cucumbers and an English-style greenhouse variety. They both did phenomenally, and both seemed to deal with the heat well. Our only complaint was that the picking cucumbers became bitter from heat stress during the hottest part of summer.

We planted three different varieties of peppers: jalepenos, a ristra type, and bell peppers. All the peppers did well, though the bell peppers weren’t nearly as prolific as I would have liked. I’m not sure if we planted them in too small pots, or if the variety we had was not ideal, but I’m thinking we won’t be planting many of them again.

Total Failures:

We tried pumpkins, sweet corn, cantaloupe, and watermelon in the greenhouse in containers this year. It was a total failure. Only the pumpkins put out decent blossoms, but even after having hand-pollinating them, the fruits rotted and fell off before maturing. We’ll use that space in the greenhouse for more tomatoes.

Speaking of failures, our onions were a complete failure this year. I bought onion starts and also grew a bunch from seed. I think the heat, combined with a very late spring, did them in.

While our fruit trees blossomed, none of them produced fruit this year. I’m not sure what that was about, but I suspect our strange spring (snow very late into the spring, then sudden, unseasonable warm temperatures) messed with the trees.

Berries:

Currants, raspberries, and rhubarb all did very well. We picked over 10 lbs of raspberries from our humble raspberry patch, and I was finally able to harvest our domesticated currants before the chickens got them. Wild berries were unbelievable this year as well. I’ve never seen larger blueberries in my life.

Honey:

With the warm summer came an excellent honey harvest. The bees had many, many days to fly and collect nectar. However, two factors worked against me this year. First, the spring was ridiculously cold. I literally had to dig through 2 ft of snow to find ground in order to set up my bee hives. I think the cold weather meant the colonies did not build up their populations as quickly as normal. Second, I had serious queen problems. In one hive, I tried to set up a 2-queen system, but for the second year in a row, it didn’t work out. In the other hive, I had a rogue queen hiding in there somewhere. She killed three other queens before I could confirm she was in there and producing eggs. What a pain. Nonetheless, we ended up with 45 lbs of honey from the two hives. Next year I’m shooting for 60-70 lbs.

Other Notes:

Cabbage, broccoli, potatoes, carrots, turnips, zucchini, salad mix, peas and lettuce all did well. They seem to be the consistently good veggies up here.

We did a bunch of canning this year! With the greenhouse produce, we had the opportunity to try canning a number of different things. We canned tomatoes, salsa, pickles, garlic scapes, and jalepenos. While the canning can be a lot of work, it’s satisfying to finally be able to preserve more of our harvest for the winter months.

The freezers are full of salmon, halibut, moose, and caribou, and the last of the yard chores are done. It’s finally time to wait for our first real snowfall, and look forward to the beginning of trapping season. Once trapping season is over in February, it will be time to start thinking about the growing season once again…

How to Make Salmon Roe Caviar

I’ve always wondered about making salmon caviar. I love tobiko and other fish eggs on my sushi, and every time I’ve thrown a skein of roe into the river as I cleaned my salmon, I wondered it I was, in fact, throwing away an edible part of the fish.

This year, I met a woman originally from Russia on the banks of the Copper River. She talked to us about making salmon roe caviar and my interest was piqued. Upon further research at home, I discovered that the UAF Cooperative Extension Service actually published a guide to making salmon caviar. I followed their recipe both times I made it, but there are much fancier recipes out there I’d like to try.

Below is the process of making the caviar.

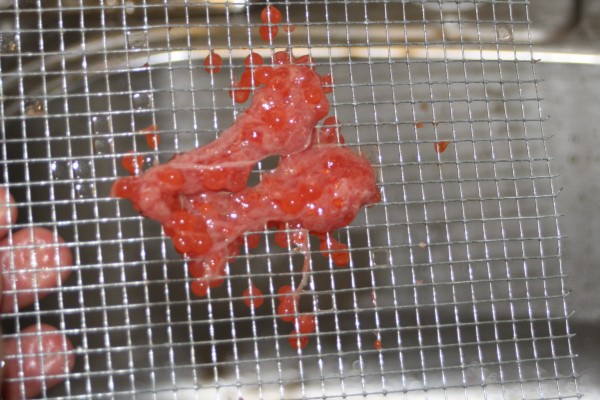

Rub the skein of eggs over the wire mesh. This will separate the individual eggs from the skein tissue.

Refrigerate. The eggs will keep for about two weeks. They taste fantastic with cream cheese, crackers, and chives. They’re also great on scrambled eggs!

In terms of taste, the eggs are almost entirely tasteless. I would argue they simply taste “salty, fresh, and rich.” More than anything, they add texture, color and richness to whatever you are serving, and they seem to be very versatile.

My 100th Post! (And a video)

This summer has been a busy one, and while I have many things to write about here, I simply have not been able to slow down long enough to actually write. (Look soon for posts on making birch syrup, making salmon caviar, milling lumber with a chainsaw and more!) In the meantime, I decided to make my first little “how-to” video. I went out with the boys and picked 10 lbs of red currants the other day to make my annual batch of currant-raspberry mead. I was dreading cleaning all those berries, then a simply idea dawned on me. (See video below.)

The Greenhouse

I’ve been wanting a greenhouse for a couple of years now, and this spring we finally made it happen. Warm weather crops like tomatoes, peppers, cucumbers, and the like are nearly impossible to grow here in Alaska without a greenhouse. While I’ve been able to successfully grow tomatoes, sweet corn, acorn squash and pumpkins here in Alaska without a greenhouse, it has required raised beds, hoop houses, and some serious luck.

With a greenhouse, we should be able to grow much healthier, productive plants. New veggies mean new challenges, which always makes for an interesting growing season.

The greenhouse is 16×10 feet, with seven foot walls. The peak of the roof is probably 10′ high. I built the floor for the greenhouse last fall just before the snow began to fall. The floor is built on 4×6 skids, supported with “linkin-log” style 2x6s underneath to keep it level. We have a pretty good slope to our yard, so while one side is ground level, the other side of the greenhouse is 4′ off the ground.

I threw a tarp over the floor this winter, then shoveled off the snow in March in order to build the walls and roof. My father-in-law had old fiberglass greenhouse panels that had been sitting in his yard for nearly 30 years. Although they were completely buried in leaf litter, they still had some life in them, and saved me over $1000 dollars in supplies. An acquaintance was getting rid of a very nice glass french door a couple years ago, which provided a beautiful (and free) entrance.

I ran out of old fiberglass panels before I got to the last side of the greenhouse, but because that side is north-east facing, with the mountainside behind it, I just covered that side with plywood that I’ll paint this summer. We shouldn’t lose much light, as the sun never shines from that side.

I haven’t built benches yet, but that project may wait until next year. For now, 5-gallon buckets on the floor should work just fine.

The plan this year is to grow 30-35 plants in the greenhouse. We’ll have a good variety of tomatoes, peppers, and cucumbers. The boys want me to grow sweet corn and pumpkins, so we may try those in containers as well. The greenhouse has already been up to 74F this week, with ambient temperatures only in the 40s, so it won’t be long!

All the best as you get ready for growing season!